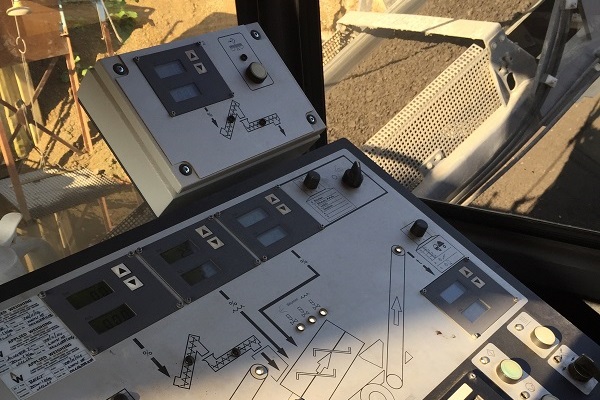

Our cold-lay surfacing materials utilise 94% recycled aggregates bound with foamed bitumen and other hydraulic binders. It uses 5% of the energy compared to the amount used in manufacture of traditional asphalt.

OCL Regeneration Ltd produces two core Foambase products that replace traditional base and binder courses.